The research in PTLUP aims at the development of plasma processes and equipment through understanding of the elementary process mechanisms. The strategy followed for the development of each process-material-application set is based on the use of plasma diagnostic techniques, combined with plasma-CFD modeling and correlated with material characterization techniques for achieving optimized material properties and yield.

Plasma Enhanced Deposition processes

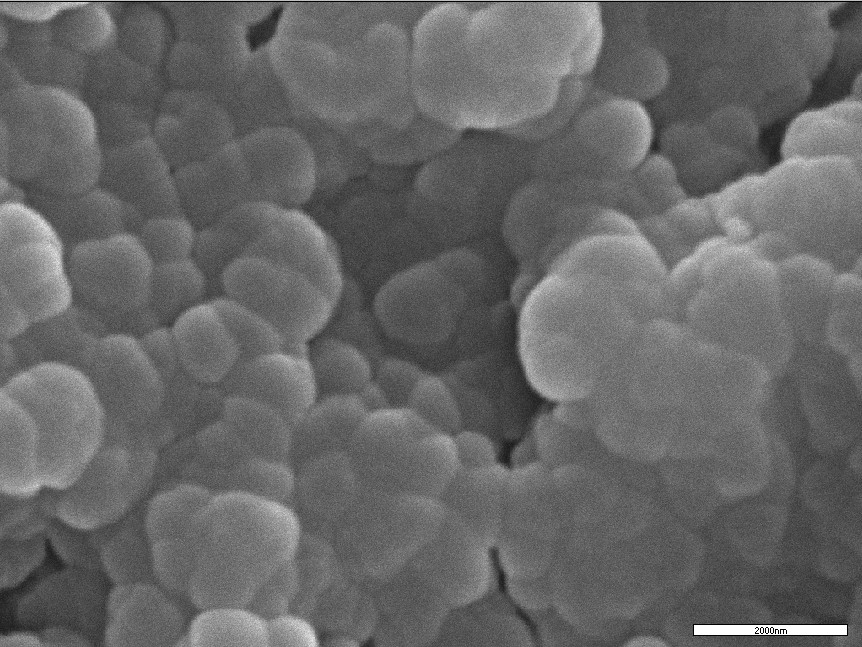

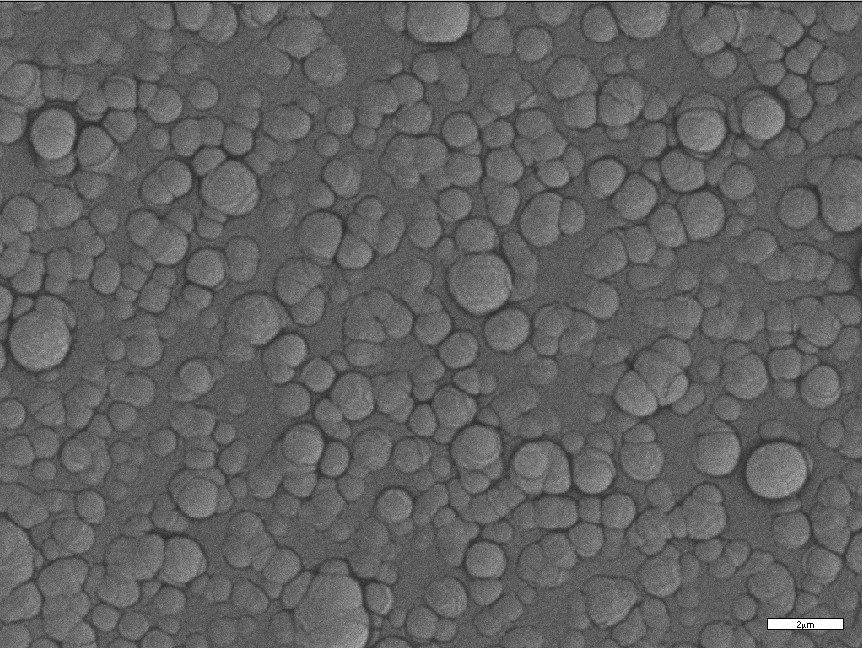

Intrinsic a-Si:H and μC-Si:H thin-films for optoelectronic applications

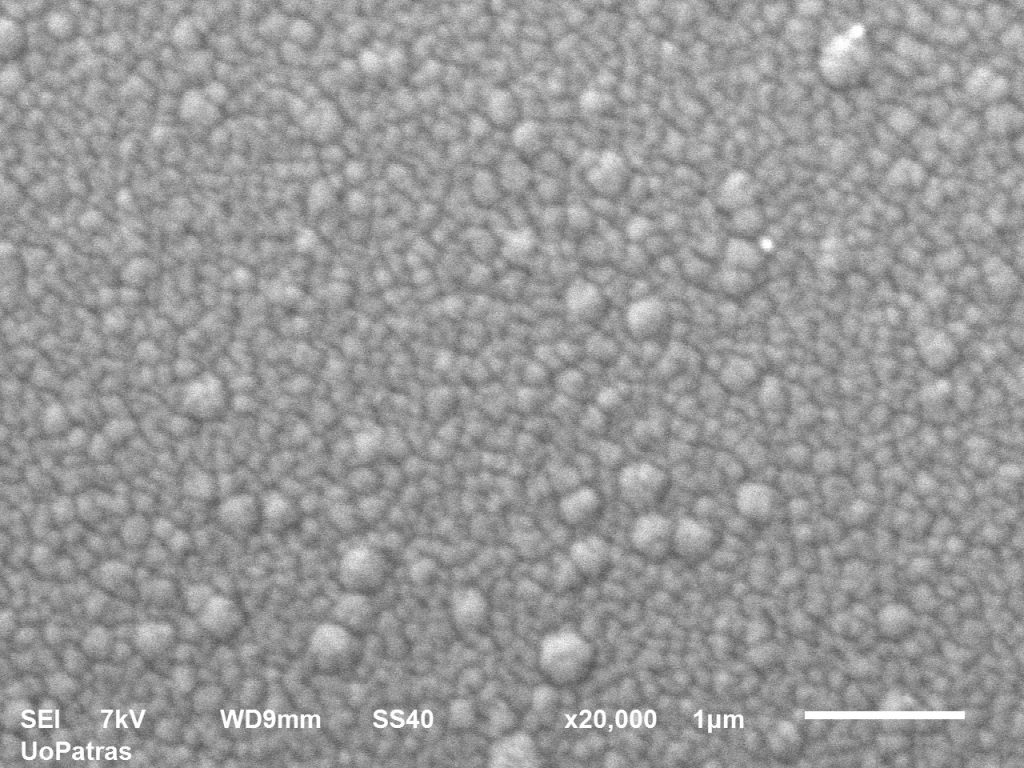

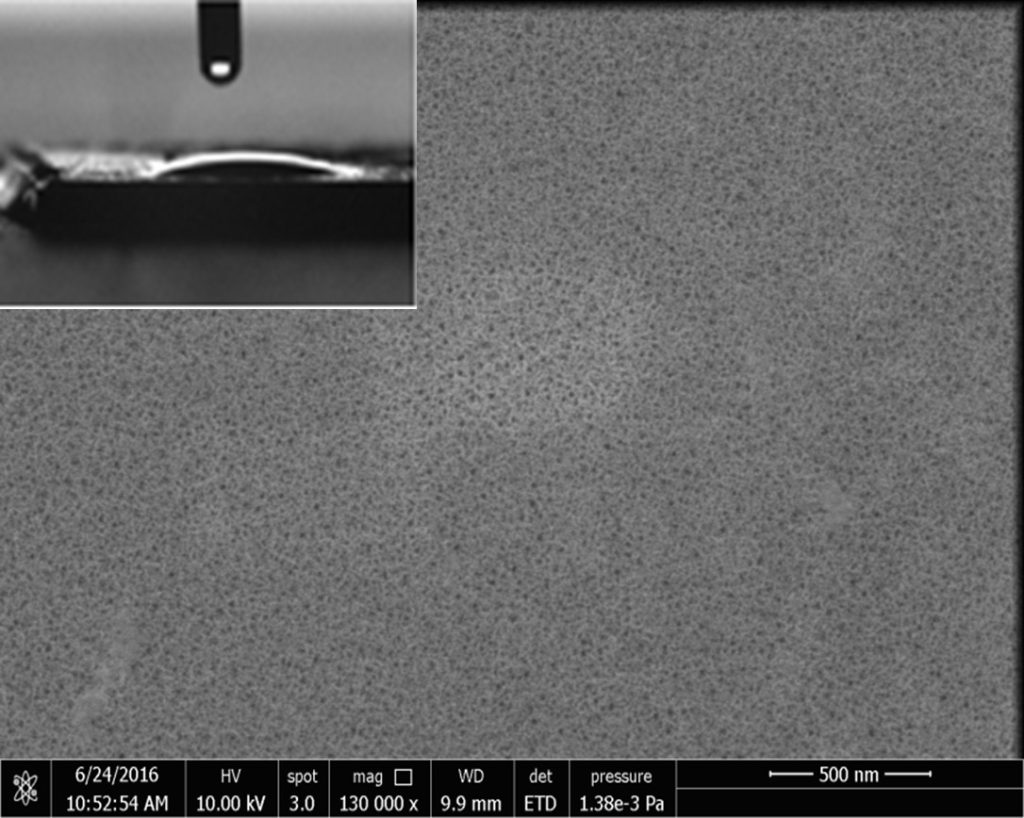

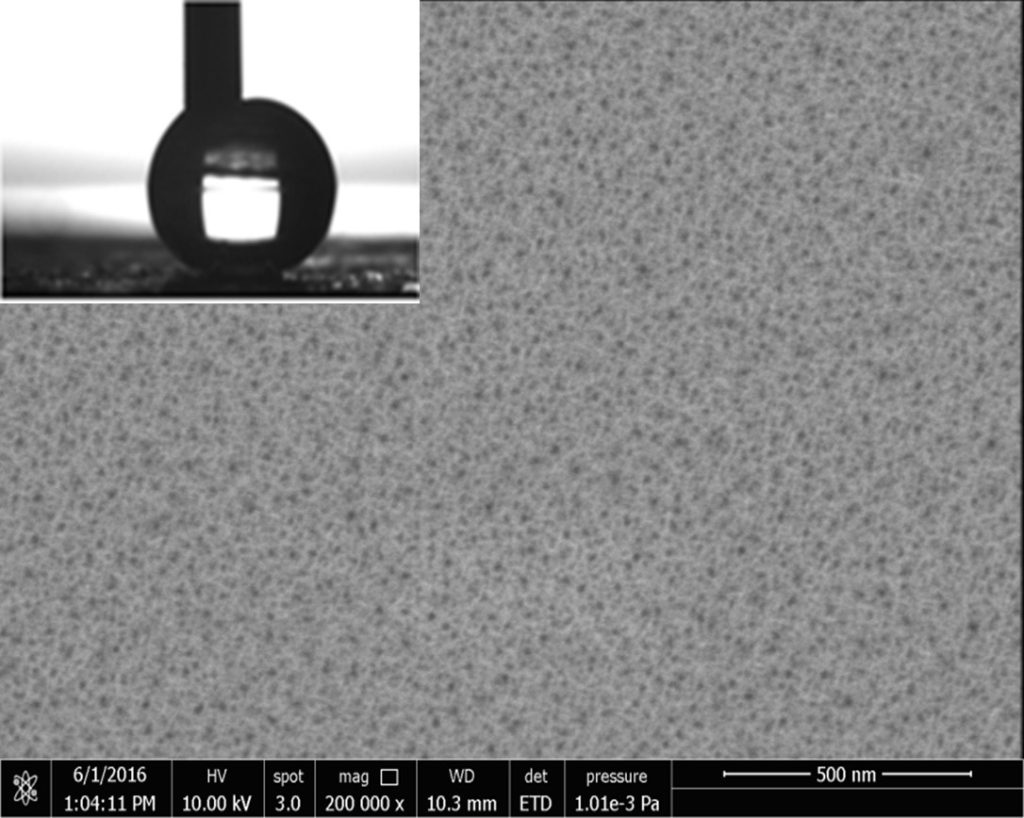

Hydrophobic, hydrophilic and amphihpilic coatings (CFx, PEO-like, TiOx)

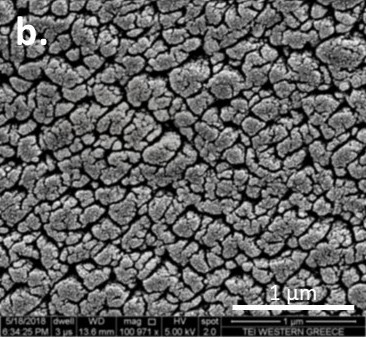

SiOx / SiOxCyHz thin films as barrier coatings (e.g. anticorrosive coatings, barriers for controlled drug release)

DLC coatings for biomedical application

Poly Acrylic Acid Films (Bio-Functionalisation)

Applications of Atmospheric Pressure Plasmas

Surface Treatment

Plasma Medicine

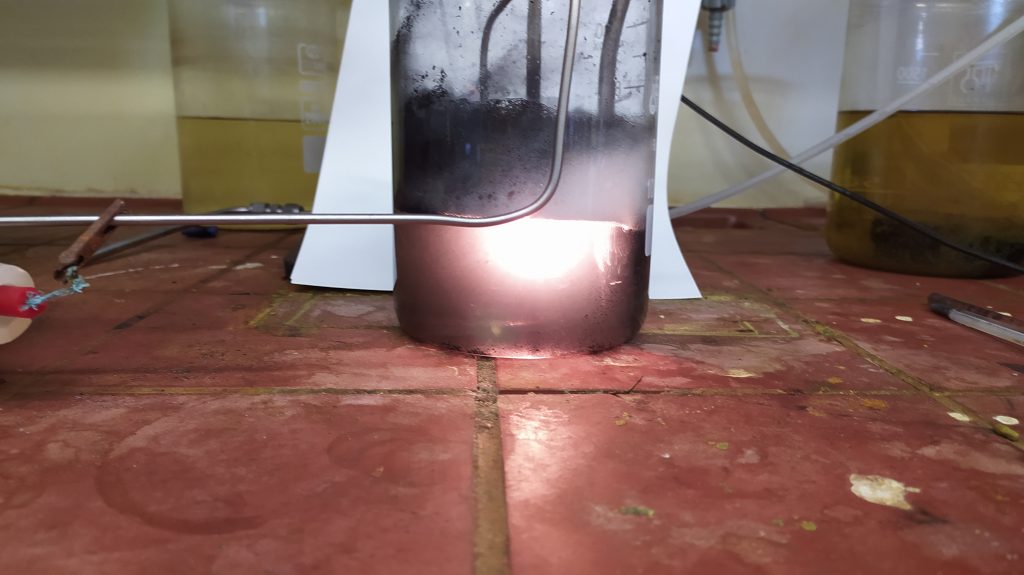

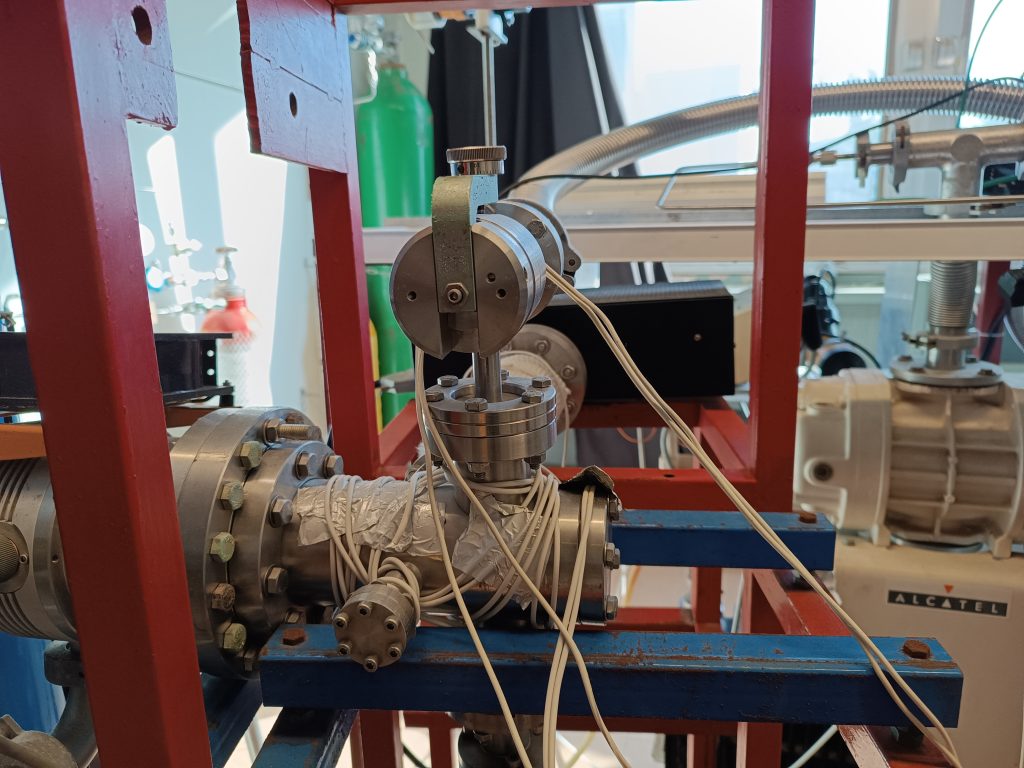

Plasmas in contact with/in liquids

Composites solvolysis

Liquid waste treatment

Bacterial deactivation

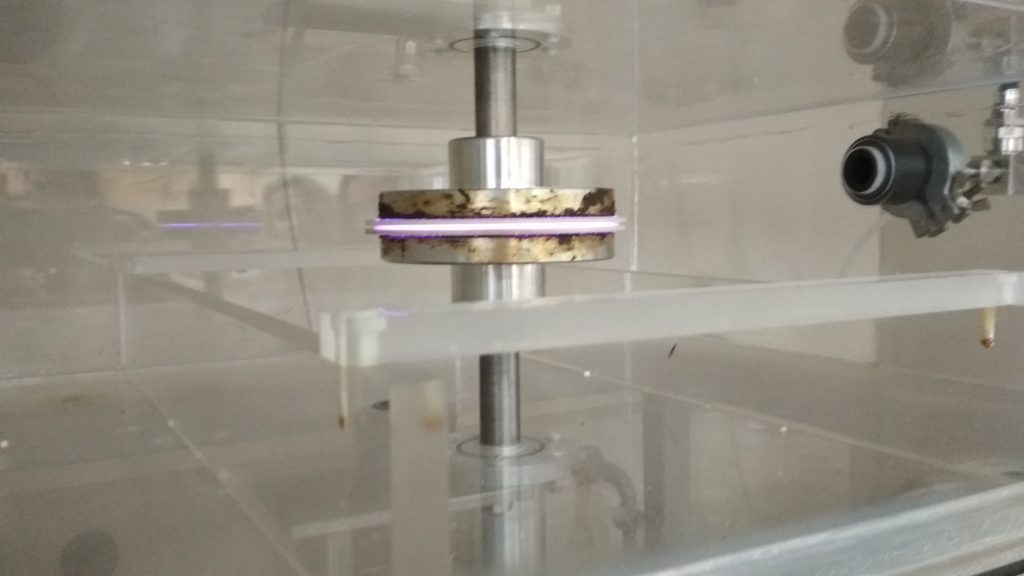

Design and Testing of different plasma sources

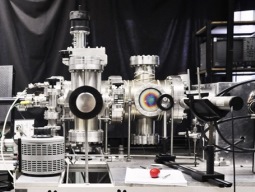

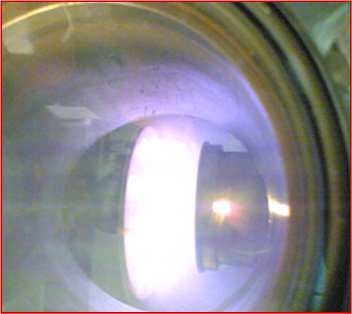

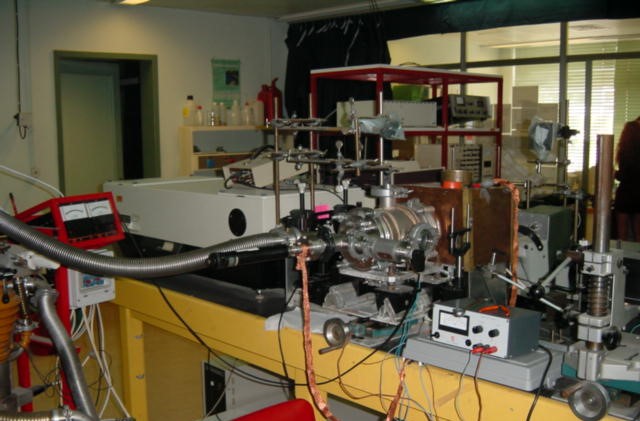

High Vacuum – Ultra High Vacuum RF Capacitively Coupled Reactors

High Density Plasma Reactors (inductively coupled, ECWR, hollow cathode)

Dielectric Barrier Discharges

Plasma Jets

Plasma in Liquids

Plasma Diagnostics

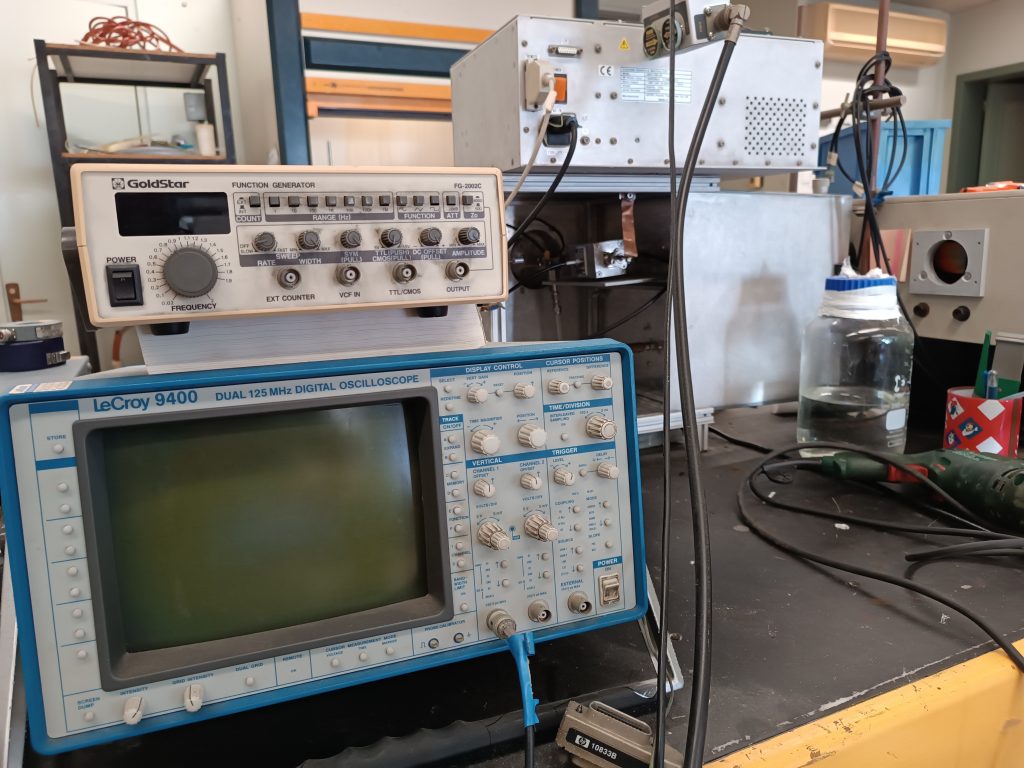

Electrical Measurements

Plasma Imaging – Optical Emission Spectroscopy

Laser Interferometry

Mass Spectrometry

Simulation

2D/3D self consistent plasma modelling

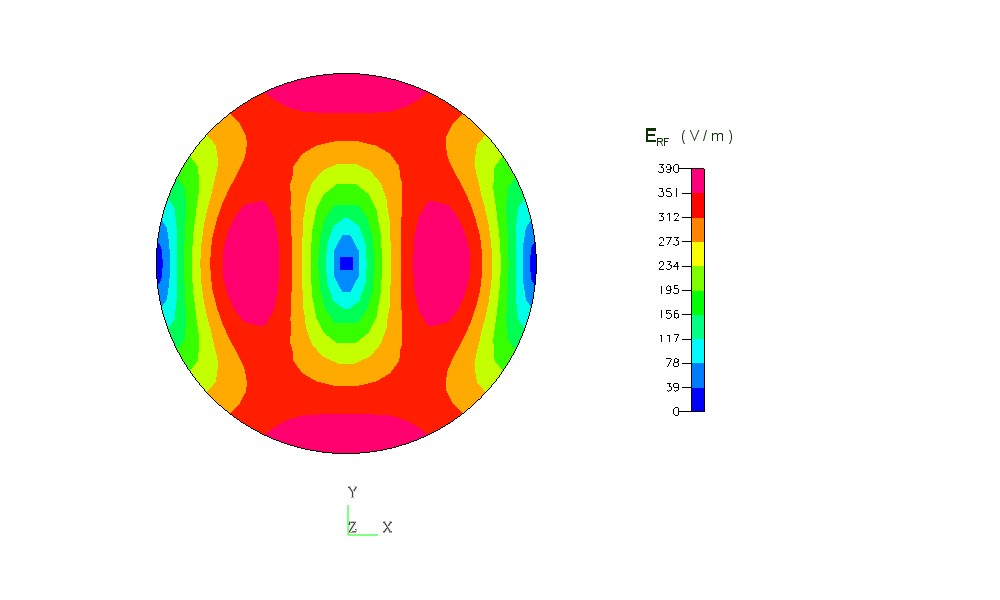

EF simulation

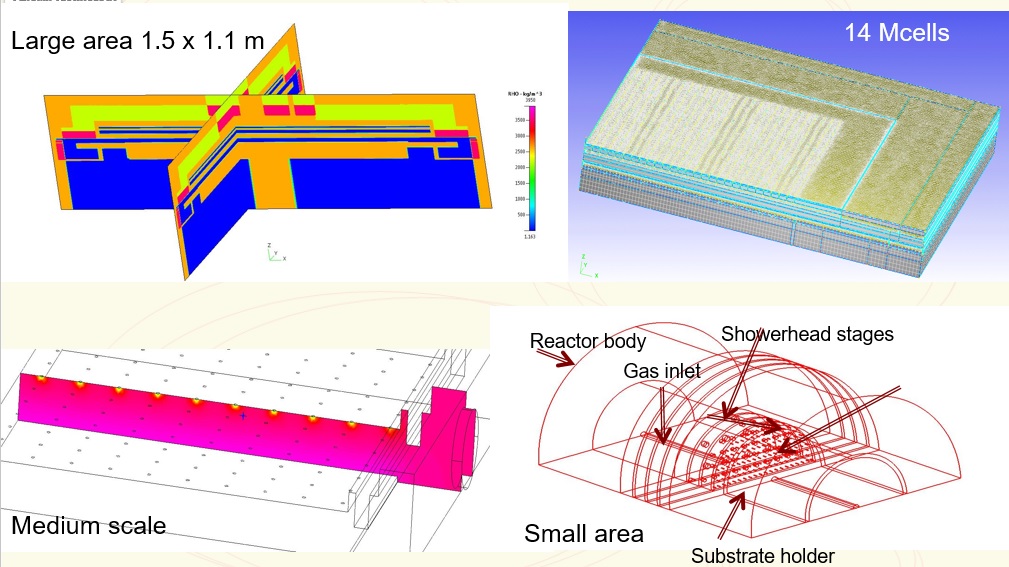

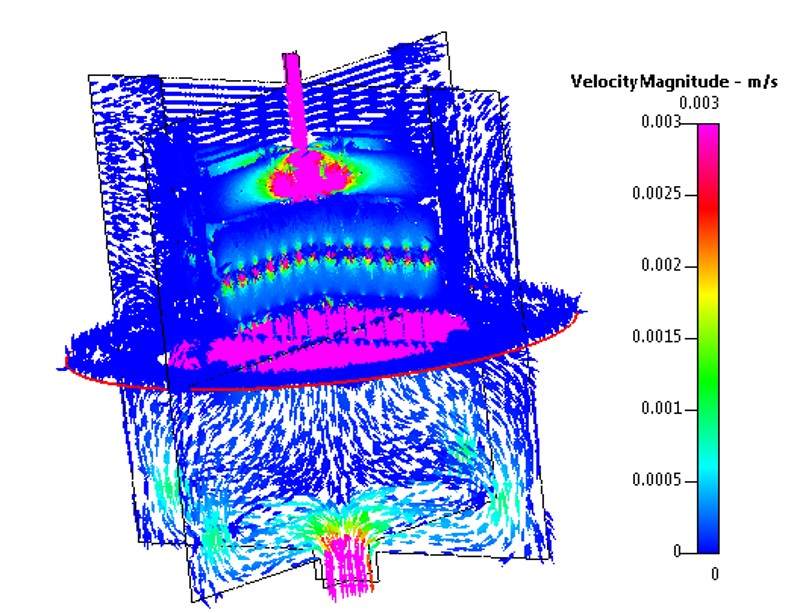

Flow/heat transfer in plasma reactors

Materials Characterization

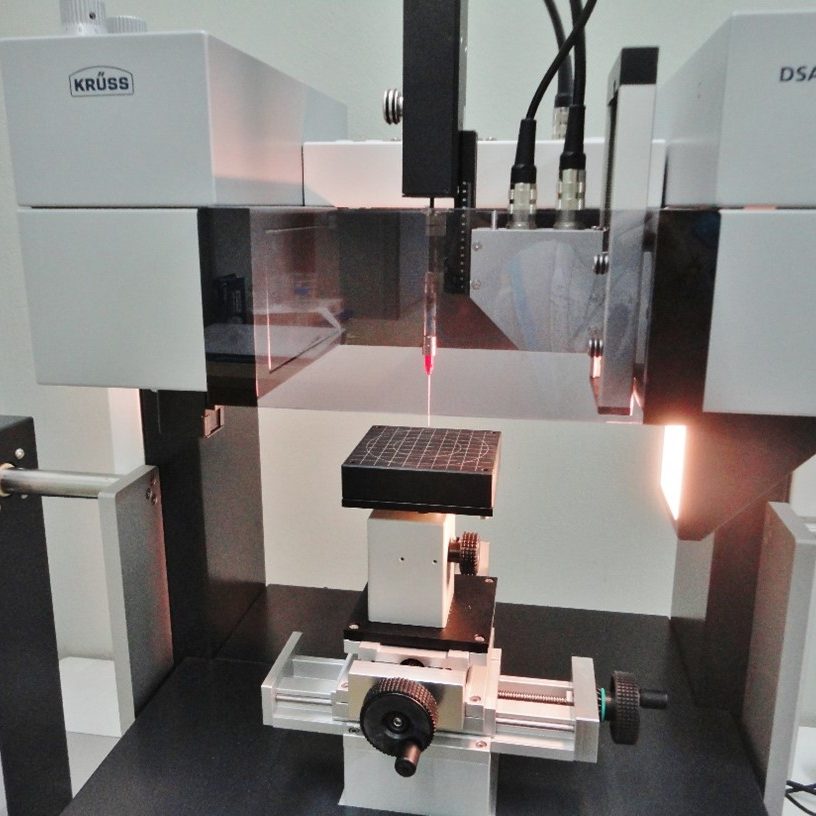

Contact angle goniometer

Scanning Probe Microscopy